Reviving lost technology doesn’t happen overnight. Over the years, our workshop has grown step by step — here’s a look at the milestones that brought us here.

2011

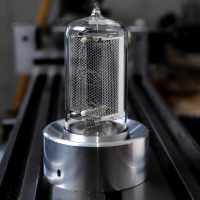

I discovered nixie tubes by accident while browsing the internet. They felt so otherworldly that I could not sleep that night, wondering how such an alien technology could once have been the main way to show numbers.

2012

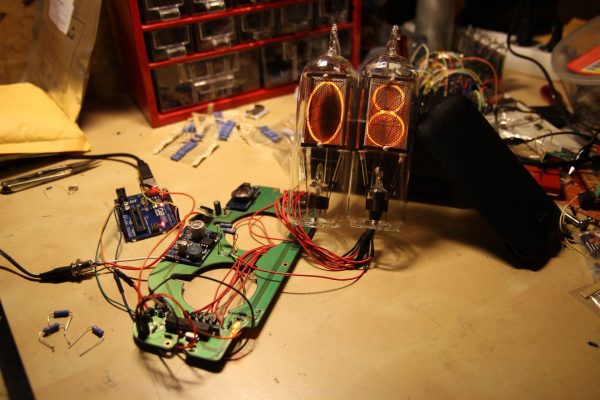

I need to experience the nixie tube glow. I ordered my first nixie tubes from eBay, small russian tubes IN-14, this was actually my first physical encounter with vacuum tubes. I made a thermometer with them. Nixies are beautiful – they deserve their place in the sun.

I need tubes bigger than tiny IN-14, however, buying six pieces of Z566M or similar means spending around $250. Quite a lot. (!) Looking at the simple glass tube and metal structure inside, I got the idea of making my own nixie tubes.

Bringing nixie tubes back to life.

I thought I would find a book with a detailed description of how nixie tubes were made. However, it turned out I was too naive – information about nixie tube manufacture was pretty scarce! But I didn’t give up. After some time, I collected basic information and got the idea of sharing it publicly, hoping to get in touch with more people interested in nixies. I eventually started to write a blog about my efforts to make nixie tubes at home.

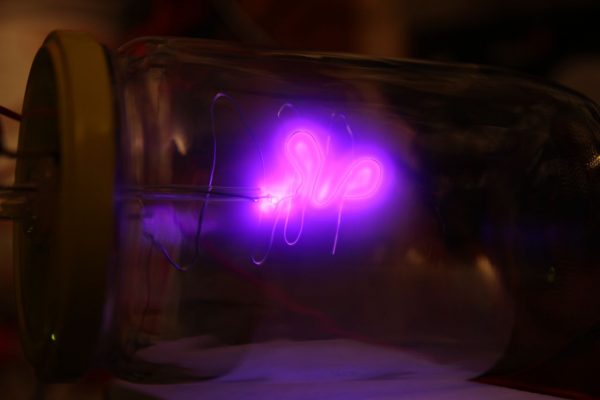

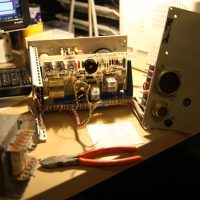

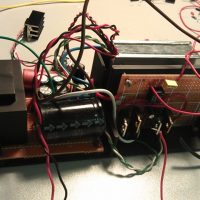

I made the first experiments with gas discharge (in air). It was pretty exciting, so I bought argon to see what the noble gas would do! The HV power supply was a must, so I built one! I also started making my own glass lathe, it never worked much well. I am setting up my first workshop in the basement of an old Baťa’s house. Not a beautifuly organized space, but this is gonna change.

In this workshop, I see a glow discharge in air for the first time.

A crucial thing happened – I was contacted by a Ron Soyland through my blog, a skilled man who had been successfully making vacuum tubes at home for ten years by then. This was the most important benefit of my blog as Ron would willingly share a lot of the knowledge I needed for making my own tubes. We would exchange more than 2000 emails during 2012 and 2013!

I got a bunch of old vacuum tubes and started to study their inner structure, seals and other details. One night, after a celebration of newborn twins with friends, I sat at the computer and found an eBay listing offering Alcatel ASM 51 helium leak detector, I was in very good mood so it didn’t last long and it was on the way to me! This machine was one of the most important addition to my shop!

It took months, but the helium leak detector is fully repaired and running! I also made another design for the glass lathe, v2.0.. I am spending lot of time with family (three babies now), but there is still time to make progress.. I set up a new glassworking torch with oxygen/gas manifold, some other torches, small glass saw, new spot welder (working perfectly), a chuck for the glass lathe and some other minor things.

Our new house is built and we are moving, I am leaving the shop in basement and building new one in attic of our new house. I now have more room, but being surrounded with wooden timbers I need to be careful with flames. I am building an oven for baking out the tubes.

To make a fully sealed tube, I need to seal-in a metal wire into glass, with a perfect hermetic seal. I investigate the alchemy of glass to metal sealing..

Next year, I want to have a tube with a bright orange neon glow!

2013

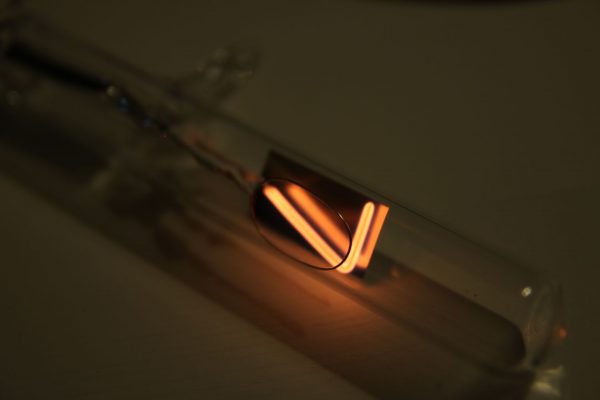

I am working on new gas filling manifold, it should be able to supply neon and argon to nixie tubes. I also made a test tube for experimenting with gas discharge. And when I finally made a neon bottle connector, I was able to use a homemade vacuum needle valve to fill a test tube with neon and enjoy the real bright neon glow, much better than argon! Shortly, I made the first sealed tube with neon – I marked it “lab sample No.1”.

I finished the bakeout oven, it will help me to achieve higher vacuum in the tube. The helium detector broke down, old transformer stopped working – I am searching for someone who would manufacture that part from scratch..

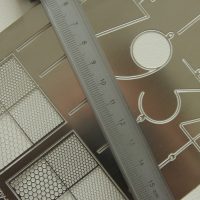

I started looking for a manufacturer of metal parts for the nixie tube inner assembly. I got samples from local company (local companies are first to ask to as I want to support local businesses), but it was of a really bad quality. I found that most of the european companies don’t even reply to my emails, thats frustrating.. I also started rebuilding my torch system to oxygen concentrators as an oxygen supply instead of liquid bottled oxygen.

One morning, I found eBay listing for a big industrial Heathway glass lathe. Great price (only £1.300), a similar piece was offered on US eBay for $12.000 recently. I checked the pictures, the machine seemed to be in good shape. The only problem was that it was sitting in England, 2000km from my shop – 800kg heavy machine!.. I decided to take a risk and bought it immediately. It turned out that the lathe comes from a cancelled university glass shop and the man who sells it is glassblower who worked there. So I paid it and started organizing a transport. It was pretty difficult, but finally, after tons of emails and calls, I found a small company that made it! They brought the lathe and put down on a concrete block in my garden that I made two years ago just for the case I will need a big machine.. There was no garden shed by the time they put it down.

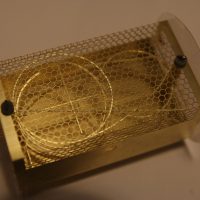

I finally found an Asian supplier for the metal parts (digits, anode grids), the quality was absolutely exceptional! And after almost half a year of building the garden shed, I finally finished it! I started moving the stuff from the attic, 35 square meters of a room just for my equipment!

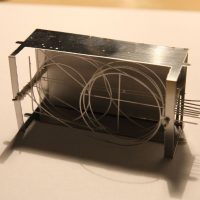

I made the first prototype of a real nixie tube, with a proper inner structure and gas mixture. Only the glass bulb was a bit weird as I had to make it from small diameter tubing.. And I also discovered a glass-art contest organized by Czech glass manufacturer Preciosa. Okay, let’s consider myself a glass artist for a while ;-)

I work only on nixie tubes and the nixie clock I designed for the contest, 10-12 hours per day in average, weekends included. I dont remember anything but the shop from this month! After really intensive development, I made it! ShanghaiTime nixie clock. The first nixie clock with newly handmade nixie tubes!

I am working on improvements to the current nixie tube. In the meantime, the ShanghaiTime clock is being exhibited in the Shanghai Museum of Glass together with 19 other glass art objects from the Czech Republic. Visitors can vote for the most interesting project, and ShanghaiTime gets a nice second prize! One of the visitors in the museum is Yan Zeyuan, a nixie tube enthusiast. Yan travelled to Shanghai and took a set of photos from the event!

Another crucial moment came to pass. I’ve just found an advertisement for a vacuum oven for sale offered by a local company.. I am calling to see whether I can come and check it out. Jumping into the car and heading to the company that deals with stuff bought in auctions from bankrupt companies. What I see there takes my breath away – pallets full of modern vacuum equipment, tens of turbomolecular pumps, controllers, high vacuum gauges, valves, system components etc.. Having no experience with such kind of equipment, I immediately came up with the idea to refurbish, test, and sell the equipment. It was the first time I actually saw a turbomolecular pump; however, I was brave (or mad) enough to offer the deal, and we eventually agreed.

The garden shed is starting to be too small for my stuff, and I am soon going to move all the equipment for refurbishment from the company to my workshop. I have to find a new room to rent. The closest place for rent is a castle from the 17th century in the neighbouring village. The rent there is the same or lower than other places around and is also closest to my current workshop. Aside from rational reasons, this place has a spirit!

I am moving the turbos and other equipment to my first room in the castle, my workshop area grows by 50 square meters to 85 total, together with the garden shed.

Goal for the next year – to build machinery that would allow me to produce nixie tubes for customers!

2014

The year 2014 was mostly about refurbishing and selling all the vacuum equipment. I can buy many pieces for myself at a reasonable price, so every cent earned goes back again to tube-making equipment. I am getting familiar with turbo pumps, roughing pumps, controllers, vacuum gauges, vacuum valves and all the other stuff. I am also building a device for the activation of getters inside the nixie tubes, called a flasher. This is the last tool I need to complete the whole production procedure of a nixie tube.

I think I am now ready to prepare the first small batch of nixie tubes. I decided to design a one-tube nixie clock and find the first customers who would help me test the whole product, from the electronics to the nixie tube itself. The tubes that I make in this time differ slightly in shape, definitely not ready for a 6-tube nixie clock – the differences would be visible immediately. I take on another room in the castle, another 65 square meters added to the workshop.

I hire accountant, the complexity of importing and exporting all over the world is now so high I need to hand over it to a pro. I move all my nixie tube activities under separate company.

The one-tube nixie clock is developed, I name it Solitube clock – a solitary tube. I sell 20 pieces of the clocks, mostly to friends who have been following my stubborn efforts for quite some time. I am receiving the first feedback from customers, great! I also hired a part time coworker Karel, he helps me with vacuum stuff refurbishment and do some small tasks on the tubes. Karel is smiling all day long and would cheer up the whole team in the following years.

Emails from people all around the world start coming. I am really happy that I have customers. I focus on simplifying the manufacturing techniques to cut down the amount of time spent on a nixie tube so that I am able to offer a reasonable price for customers. The price settles on USD $175 per tube, which covers the manufacturing time, shop rental, and also keeps some profit for other investments into equipment. I am still running on household savings, which are shrinking fast..

The nixie tubes from my little lab reached first customers. First nixie tubes produced since the old factories were closed. Sure, they won’t live long (I dont know that yet), but it is an important milestone.

2015

It has been 3 years of very intensive work on nixie tubes now, 10+ hours every day, weekends included.. A goal for this year is clear – to break even financially, and cover all expenses from our sales.

The R nixie tube development is finished – at least thats what I was thinking at that time. Later, I would learn that the development of the nixie tube is never finished – there is always something that will challenge production!

Most frustrating part of the nixie project so far – my first customers report failures of the early tubes (under serial number #200). This sends me back to the lab, and I spend months testing individual materials, gas pressures, gas mixtures, gettering processes, cleaning processes, and many more. The cause is soon identified – improper curing procedure of ceramic adhesive inside the tube, uncured compound slowly outgasses, spoiling the gas inside the tube. The overall processing of the tube is re-engineered. Since then, I decided not to underestimate anything in the process – I kind of developed a paranoia related to the processing of the nixies. Just to make sure I will never experience a situation like this again.

I am making 100+ tubes as replacements for the bad ones, ouch! Half a year of work.

Our twins go to kindergarten, Eva (my wife) joins me and took on administrative work – invoices, bills, cooperation with the accountant etc.. This is big help as I can spend my time on R&D and not get demotivated by piles of papers..

I rented a new room in the castle, made it a kind of clean room, and moved the entire process of tube manufacture into it. The process is now cleaner and well organized. I am spending a lot of time on building new pumping station which will achieve the same high vacuum levels as the old one, but will be much faster and easier to operate.

I had been watching the amazing work of Berlin-based designer Frank Buchwald for quite some time – his industrial-monster-insect style is just unmistakable. When I see his Nixie Machine he made for M.A.D. gallery, I simply have to meet him!

The goal for 2015 was accomplished (to not lose money). Goal for 2016 – get rid of other activities, focus on nixie tubes only.

2016

After months of hesitation, I hired my first full time employee (Monika), finally! Now I am able to delegate some tasks and devote more of my time to development.. I also finished a new pumping and filling station for my nixie tubes, which will speed up the manufacturing and also provide a bit more consistent results.

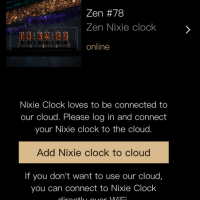

First revision of the long-promised six-tube clock board is out! I name it ZEN nixie clock, a calm and peaceful way of displaying time. One feature for all – it is connected to the internet and all the settings (time zone, display effects) can be adjusted in real-time from the user account on our website. Also, the time is synced automatically from the internet.

I am working on making the production of R|Z568M nixie tube more and more efficient, focus is also on little details. It turns out that hiring Monika was a great decision, she learns fast and does a great job. I also finished some interesting projects – a set of nixie tubes for Clive Maxfield and his wonderful steampunk-style clock. Another finished project is a Sturnus clock, which was made together with Daniil Kondratyev under the Glowguardian studio.

We’ve just made R|Z568M with serial number #800, unbelievable! The most time-consuming task for this month was identifying software bugs in the initial revisions of the ZEN nixie clock.

We have the first Zen Nixie Clock boards among our customers, collecting feedback and improving the firmware. One of the demands is for a case that would protect the tubes and provide a decent-looking way to showcase the Zen clock. So, I am designing a minimalist case with an aluminum stand and glass cover.

Small prototype run of Zen Nixie Clock is finished. We have manufacturing processes set up and suppliers for all parts we don’t produce ourselves. I opened pre-order possibility for the clock, limiting it to 10 pieces only to make sure the clocks will be manufactured on time (in September) without delays.

I deliver over a hundred tubes to Duncan Hellmers for the Blub Keo single tube nixie clock.

I am receiving 10 orders for Zen clocks immediately, and I am accepting more orders with uncertain delivery times. The production of tubes is running without issues, as are all other parts, except for the aluminum stand. Our supplier (Europe-based) is unable to achieve the same good results as in the first prototyping batch. We need to order machining for a new batch of stands, but shipping is delayed.

The video documentary covering the manufacture of nixie tubes at our lab is finished and published on YouTube. In a few weeks, with 500k+ views, it will become the most popular vacuum tube-related video published on YouTube. We attract customers beyond the group of nixie tube enthusiasts, which brings us new orders. The first Zen clock batch is not yet ready, getting bad news from the manufacturer. I am changing the supplier of raw material and also the machining supplier (still keeping production in Europe).

We still don’t have anodized stands for our clocks, our supplier tried four batches with horrible results. I keep searching for a good supplier.

I deliver nixie tubes for the first two Bombe clocks by Paul Parry (Bad Dog Designs).

New orders for Zen Nixie Clocks and our nixie tubes are still coming at a steady pace. It’s clear we will need more room and help. I am renting three new rooms at the castle, doubling the total area to 250 square meters (2700 square feet). The financial situation is getting better, so I risk hiring another team member (Katerina) to train her in glassblower tasks. We purchased a set for etching metal sheets to enable rapid prototyping and development samples. To speed up production, we acquired a fully automatic laboratory washer for washing tube parts prior to assembly, replacing the manual process.

We end the year with $125,000 in sales and a $25,000 profit. I devoted almost all my time to the development of nixie tubes; no other activities were undertaken in 2016, and the goal for that year was accomplished.

2017

The Zen Nixie Clock manufacturing is running at a steady, but slow pace. We shipped over 100 clocks and received terrific feedback from customers!

M.A.D Gallery released a very high-end clock by Frank Buchwald. Gallery, its name is Nixie Machine II and it features our R|Z568M nixie tubes. The electronics was also developed in our lab, it has all the neat features you know from Zen clock.

In February, I joined a Value Manifesto project founded by Timo Niemeyer. This project is so different from our other projects, cant wait to see it alive!

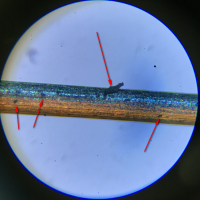

I was reported of several multiple failures of our tubes, leakage. It was clear we have a problem in sealing again.. I stopped production and spent a whole week in lab. Contamination of the sealing wire was identified as a cause.

I am starting work on the next model of clock – Puri Nixie Clock.

Summer was mainly about improving the reliability of our glass-to-metal seals. With current manufacturing techniques, we experienced 2.3% tubes fail within 6 months from manufacturing date. The whole process of manufacturing glass-to-metal seals was revised, starting with material selection, quality control, leak checking, etc.. The last batch of 400 tubes shows 0% failure rate so far.

With the team waiting for me to figure this out, I was sourcing tungsten wire from all around the globe and analyzing its cleanliness and surface quality. Eventually I found super high quality manufacturer in USA. Ten times higher price, but quality wins.. It would pay off in following months.

Past months were pretty much frustrating and I swear the failures must never appear again. In the following months, I would reorganize half of the manufacturing, standardize quality control and cleaning of all incoming parts, and develop better leak checking procedures. Since tube #2500, the failure rate drops from 4% below 1%.

Production runs perfectly, in addition we have beautiful autumn here. Daniil, a light bulb designer came to spend a month with us. Sebastian (student of electrical engineering) came for a month-long internship and seamlessly joined our development processes. We reached $30k monthly sales, our best month so far. Life can’t be better.

Guys left home and all suddenly broke down. A problem with our payment gateway appeared and we would not receive payments from customers for six weeks. I just signed a contract for a new website, which will be our biggest investment so far. One colleague struggles with serious health issues, another colleague might leave because of health issues of a close relative.

Life can’t be better.

Money issues solved, payments are flowing again to our account. I am finishing the mechanical design of the colon tubes. We are working on a new clock case made of concrete with Gravelli. I take the clock for EMC testing, passing!

We close the year with a small profit – we now have funds for development of a new burn-in machine!

2018

We started working on a mobile application for the control of our clocks. The app should be easier to use than the web interface. I am curious to see the results. January was also a record month in sales, and exhausting, no further R&D was done – I can devote my time either to making of nixie clocks or doing development..

Most of the clock orders from 2017 were shipped, on 15th I am opening orders again – and receiving tens of orders instantly (thank you!). We need to work on optimizing of the manufacturing.

After 5 years of investing into the nixie tube development, I finally have some income from it privately – I employ myself in the company as well. For a minimum legal wage – but that’s (hopefully) just a start!

Monika, unfortunately, decided to leave. She would train Lenka (new employee) for tube assembly in the following two months. I also need help in the office – I am hiring my sister Renata, she will communicate with suppliers, customers, and take care of packing and shipping our products.

Important addition to our machinery – I acquired two machines for sealing vacuum tubes, my first commercially made machines designed for vacuum tube production! This will help us manufacture different tubes in the future. At nixie tube #4000, another set of improvements was applied to our glass-to-metal seals, lowering the leak failure rate close to 0%.

I am making a simple machine for cutting getters from strip, this is first project with usage of several pneumatic cylinders. And I finally get my new Prusa i3 MK3 printer!

I finally finished development of the colon tubes (separator tubes), it took me two years from idea to a working sample ready for production. There were many unexpected issues over the time and I often felt it was a mistake to start with it as the resources spent on its development were so high. After plugging the colon tube into the clock for the first time, I immediately knew it was a good decision to make them – this little detail makes the clock!

The castle is getting new windows – we need to prepare all rooms, cover all equipment with plastic foils and then tidy all from dust. We will save a lot of money on heating costs in the future.

We develop the first version of the packaging for the Puri clock.

June is practically only about preparations for Maker Faire in Prague – the first Maker Faire in the Czech Republic. I make several experimental projects – an argon-filled tube, a red coating for our tubes, and a display with 22 tubes.

I met Radim, local student of electrical engineering. Together we make a new cleaning system for parts for our nixie tubes. With Gravelli, we made a nixie clock with a concrete stand.

We finished development of the new clock – Puri Nixie Clock. A four tube clock with even more simplistic design. I picked the best from Zen clock and added some new features as polished bases, electronics hidden in the stand and some new safety features.

We’ve got a fresh reinforcement.. Sebastian, a fresh EE graduate, joined our team. He already spent a month on an internship here last year, so the arrival is seamless and maximally efficient. Now the development of electronics will run at an elevated pace!

We attended the top Czech design event of the year – Designblok. My expectations were totally different from reality. We spent much more cash than I expected and got fewer orders than I expected :-) But we also established some cooperations there, so at the end of the day it might be worth the effort.

I decided to revive our YouTube channel. I believe I managed to distribute the work among my colleagues effectively, so I hope to find time to document our successes and failures for our followers.

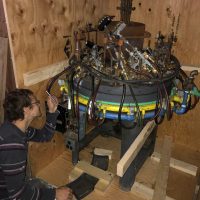

We are intensively working on a new burn-in/testing device for our nixie tubes. The main person in this project is Sebastian and he is pretty good at it. The progress is (as usual) much slower than I expected, but the result already exceeds my expectations. In two months, it should be ready.

2019

Radim is prototyping new motion sensor for our clock – with this module it will be possible to turn on the clocks automatically only when there is someone around. This will prolong tube life and decrease power consumption (which is only 5-7W anyway). But first we need to get real field experience in testing!

I started working on redesign of a Blub nixie clock, a single tube clock. This project was initially designed by Duncan Hellmers and introduced in a Kickstarter campaign, but never took off. I really liked the sleek and simple design, so we agreed on taking over the project.

It seems we have a new problem in manufacturing. Difficult one. Some of the tubes develop a foggy layer on the internal side of the glass. Seems like a simple thing, but I can’t find any correlation to our manufacturing processes and materials.

Okay, problem solved on the last day of April. We had to stop manufacturing completely and fully focus on the problem. It is quite interesting and, as expected, pretty complex. I want to devote a separate article or video to it. It deserves it as it cost us over $20,000 in salaries, material (for rejects and tests) and analysis.

I feel I need to reward us for solving the fog problem. Something that would make me smile every day. Still not the right time for V8, so I am buying white paint for walls, white paint for the floor, and white racks for storing equipment. My kids totally love the result :-)

We are catching up, Nixie Machine III was revealed, OOO clock was delivered to Grandhotel Pupp and we made significant progress on the new burn-in machine. And a new, very exciting project is in the pipeline!

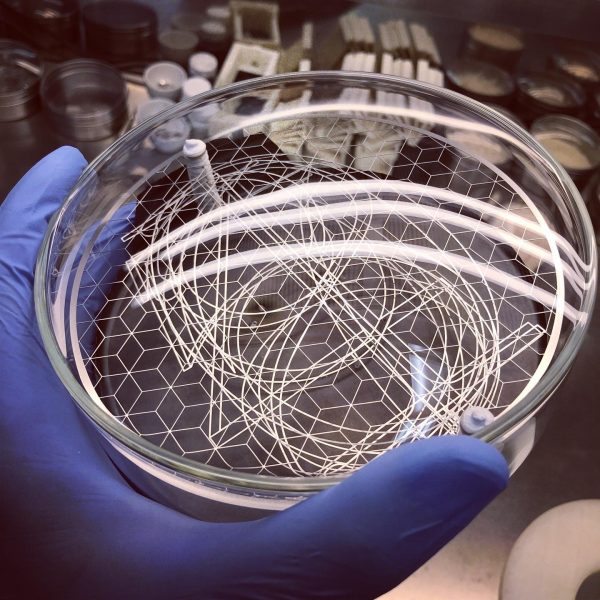

I’ve been working on a new tube project for quite some time – one of the most important parts is a stem (the glass/metal pins connection). The first results look so good!

We are testing the first prototype boards of the new nixie clock – a Blub Clock. The Blub clock will be our most affordable nixie clock. But to get our price as low as possible, we have to be very efficient and polish the quality/reliability of the electronics as well as the ease of the assembly/testing process itself.

After one year in development, Sebastian finally finished the new burn-in machine. There are still things to do (mainly fix some child diseases), but it is important that it is running and from now on we are collecting loads of data from the burn-in process of nixie tubes.

An impossible thing happened: a big box with one important piece of old machinery arrived at our storage place. This piece will play a major role in the development of our new tube model! But first, we need to refurbish it :-)

Sebastian worked for us for more than a year and he developed several projects that improved our nixie tube production – the new burn-in machine being one of them. Thank you!

2020

Finally, I am making a decision to take a separate room for my office. In the 3rd floor. Suddenly I can spend more time in “deep work” without being constantly interrupted by the buzz in the production. And I have time to make videos for you on Youtube!

Umashimenkana project – this is gonna be big, literally. A 5x5m wall installation, covered with 121 brand new nixie tubes – 150 mm in diameter. Now we only need to develop this tube :-) More on our Youtube channel. Deadline fortunately moved from October 2020 to summer 2023, enough time for development!

We are starting cooperation with Nick Stock – Nick will stock our clocks and tubes and send them locally to our US and CA customers. This way, we will deliver faster, without the hassle of the import process and at a slightly lower cost.

The H-tube project served as an impulse to get into a project of a machine for the production of oxygen for our gas burners.

After months of putting together parts and tooling for the new H-tube, I attempted to make the first prototype. The chances to succeed were small and it was a fail, but I discovered millions of weak places for improvement. I believe I will see it glow soon!

In order to optimize the manufacturing processes, the ladies kicked my R&D mess out of the manufacturing space. I am taking the last rooms at the castle, the plan is to turn them into a psychedelic white lab-workshop.

The H tube is glowing! However, its manufacturing is a total nightmare and that is what we need to change. I am starting working on Iteration 1. The good point is that the electrical parameters are 100% as we expected. Cool.

… 400 hours later, the 4 new rooms are ready for moving in. 3000 lux, I am getting snowblind every time I enter the workshop. But the camera loves it, with 100 ISO all the time.

2021

How good would it be to be able to see the composition of the gas inside the nixie tube? It would help us to understand better the physics behind the nixie tube and what influences its longevity. in January we’ve finally got the new lab into shape and can continue on building a system that will analyze the gas for us.

It took us some time to scale the 4 digit Puri clock to 6 digit version, but I think we did it well. It is a little monster, more than half a meter long, and that’s what we like on nixie clocks :-)

All the stuff from the previous workshop has been moved to the new room. White glossy floor, white walls, unforgiving space that forces us to really keep it tidy. And that’s good when you occasionally need to bring in some vacuum equipment or tools from manufacturing.

Recently, with Covid-19, everything became busier. We have more clocks to make (thanks to you!), there are more projects to develop, we work on the organization of our workshops and labs. This gave me the courage to hire a new colleague – a worker for manufacturing the nixie tubes. There were a lot of applications, we ended up hiring two people. Eva (a biophysicist by education – let’s hope for a hidden talent) for that particular position and Jiří, a machinist. A lot of work with training ahead!

Finally, we have the first fully working H nixie tube. After all the frustrating problems. No internal shorts, no cracks in the glass. But that was easy, the difficult task is to bring it into production and make it reliable, consistent and profitable. There is so much handwork on that nixie tube!

We got a new tool for our lab – a laser engraver/cutter. It will help us to prototype metal sheet parts faster and more accurately. I can’t wait to see it making those various small metal tabs for the H tube!

This year was a year of Covid-19, customers spent more online, so our revenue increased. We invest in scaling up production to cover the demand from customers. Thank you!

2022

Our team got a bit bigger again. Gabriela will learn assembly work on the nixie tubes, will take care of the inventory, and prepare your orders for shipment. We hope that your orders will arrive to you faster!

Eva has moved from the assembly of the nixie tubes into the lab, where we can fully use her potential.

The last problem in the development of the H tube was the oxidation of numbers (steel discoloration). Some of the methods to solve the problem looked magical. We used dry ice to create a smoke simulating gas flow in the glass. Now we know how to prevent oxidation.

Sometimes old things just need a little care to be perfectly functional again. We’re really proud of this vertical lathe. It needed a few adjustments from our machinist Jiří, to clean it up, to replace the feed lever, and some other stuff.

The first days of H nixie tube in series production came. It was a long way with many problems, experiments, failures, and time spent in development before we arrived here.

The following steps will be about the development of tooling and procedures to get to reasonable costs of production.

We’ve added a new seat to beautify our touch with you.

A place where the videos, photos, and texts we use to talk to you take shape.

We have a new toy – a small CNC milling router.. We need to prototype parts faster and begging suppliers to make something for us is more and more frustrating. So a new machine is acquired!

The H nixie tube for the Umashimenkana is slowly evolving in front of our eyes. We hope to meet a deadline next year.

In 2022, the “online purchasing fever” is over, our revenue decreases by 23%, profit is basically a black zero. What is worse is the inflation – over 15% in one year, this is something we haven’t seen in the Czech Republic since 1993. Material, rent, electricity – all goes up, eating our margins. And employees are losing purchasing power – we will need to find a way to compensate for it.

2022 was a wild year, to release a pressure before the end of the year, we made a fun video together.

Best wishes for 2023 – Video

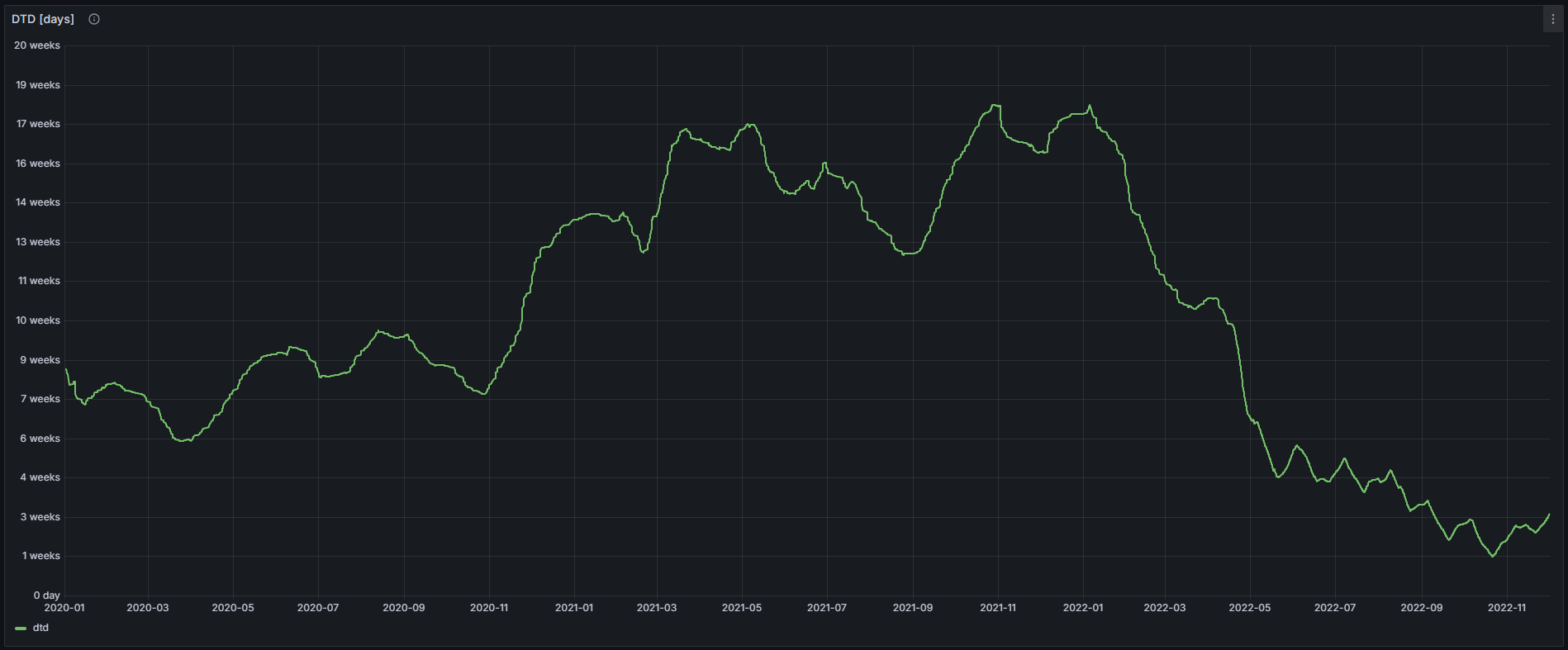

As for the DTD (“days to death”) metric, from the 2021 all time high at a value of 19 weeks, we dropped to under 1 week, sometimes just 1 day reserve. In the second half of the year, we have invested into development of the Urwerk Space Time Blade – an investment that will be paid back in the following years. For this reason, the end of the year looks quite dramatic – but there was the certainty of positive cashflow in the following period.

2023

Umashimenkana is about to be installed this summer, we fine-tune the electronics, manufacture some spare H nixie tubes and ship two pallets full of parts to Japan for installation. It is travelling by a ship, so it takes time.

We are trying to improve the assembly process of prototype boards using the LitePlacer pick and place machine. We want to make the painstaking process of putting hundreds of little parts on a prototype board faster.

Meanwhile, we are producing Puri Nixie Clocks for our customers. Among the standard production, we make another batch of nixie tubes for SIMULATEDO project.

After 3 years of intensive work, the Umashimenkana artwork was finished and installed at Hiroshima Museum of Contemporary Art as part of Alfredo Jaar’s art exhibition. The result was 100%, I still can’t believe we pulled it off.

2024

A new Nixie clock is in development. Building on the clean, timeless design of the Puri Nixie Clock, this new model will introduce exciting new elements. Stay tuned!

The Puri Nixie Clock has officially reached the end of its production run.

Thank you, Puri Nixie Clock, for an incredible journey. For the past six years, you’ve been at the heart of what we do—our mainstay during challenging times and a source of pride in our craft. To everyone who chose the Puri Nixie Clock, thank you for being part of this story. Your support kept us going and made it all possible. Here’s to the memories and to the future ahead!

2025

This year will be mainly about one aspect – bringing the new Omnixie clock to our customers. Our focus is on strictly following the production plan, meeting the production quota every week. Through improving of the organization, we want to achieve making our production more economical and the price tag more friendly.

We started the year with 6 full-time employees (Lenka and Eva S. in manufacturing, Jiri the machinist, Lukas the electronics engineer, Eva F. back office, and Dalibor trying to hold it all together :-). As planned, Lukas leaves in February – from now on, we are outsourcing the electronics engineering.

At the middle of the year, we have the production plan complete without missing a single week. From time to time, it needs an extra hour to meet the plan, but it works – I can finally predict the production output, costs, etc.. Do some real planning.