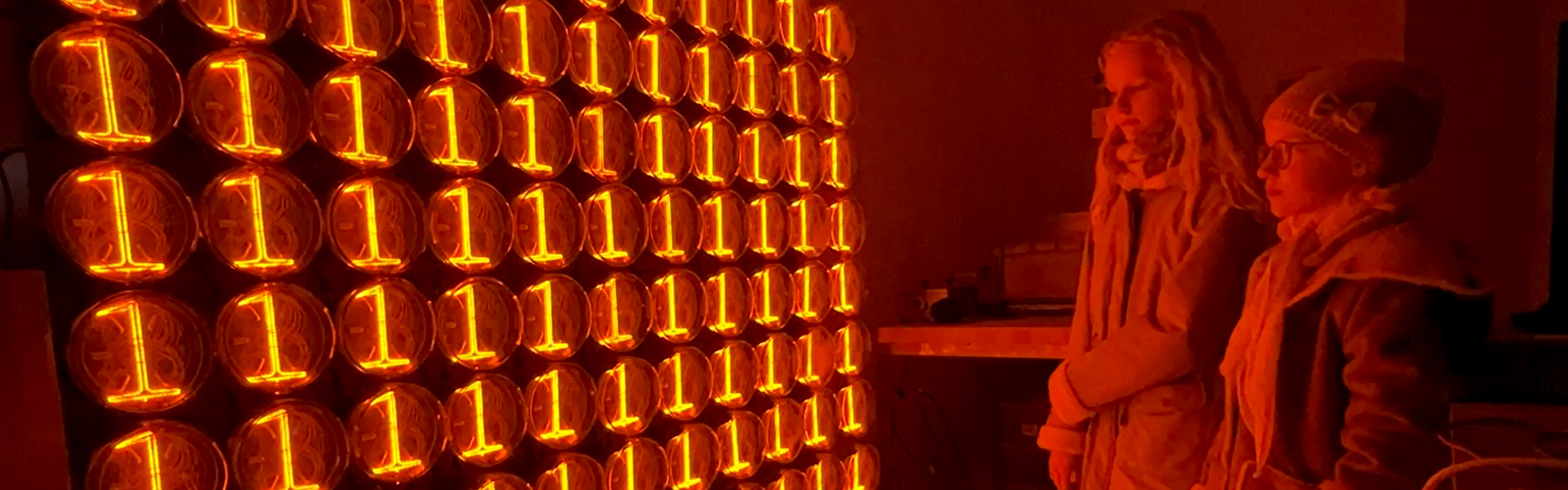

The H Nixie Tube is an experimental large-format nixie tube with 135 mm tall digits inside a 150 mm glass envelope. Originally developed for Umashimenkana art installation, it is now undergoing further refinement with the goal of reaching small-scale lab production.

Current Status of the H Nixie Tube Project

We are currently refining the internal structure to improve both mechanical rigidity and manufacturability. Our goal is to begin limited, lab-scale production in the near future.

Story of the H Nixie Tube

Nixie tubes used to come in various sizes and shapes, but their production came to an end in the last century. Their beauty was revived once again by the curiosity and enthusiasm of Dalibor Farný.

This is how the nixie tubes for our regular clocks were created. But the desire to improve and advance has brought special projects to the company. After all, the creation of the H Nixie Tube is also attributed to a project.

New art installation?

“I picked up a phone one day and on the other side was speaking the well known American artist Alfredo Jaar. He shared his idea of his next artwork with me. Ideas immediately started flowing through my veins, as well as the desire to dig into it.”

Beauty of nixie tubes is flowing into the world of art again, this time with a different task. Previously, we worked on an ambitious conceptual piece with the letter-shaped nixie tubes for the SIMULATED project.

A new one-of-a-kind creation

However, the visualisation of the project with our R nixie tubes was not ideal – the R nixie tube was too small for such a project. Creating something so complex with thousands of hours of development for a single installation would be madness, utterly unimaginable in terms of cost.

That is why from the very beginning, the idea was to develop the H nixie tube and seek ways to reduce the production costs, enabling its production in smaller series repeatedly for future projects.

A solid base

The main task was to maximize the use of the knowledge and proven processes from the production of the R nixie tube.

Glass, mechanical construction, materials, gas mixture, etc. These were utilized to minimize the occurrence of complications.

What Was the most challenging part?

One of the most demanding stages was the sealing process, where we faced recurring issues with glass cracking and oxidation of the digits and grid. Equally critical was ensuring complete electrical reliability—avoiding short circuits between internal components became a major challenge, especially as even minor variations in glass geometry caused the entire internal structure to vibrate during operation.

Some Details Still Need to Be Refined

We’re not quite at the finish line yet. Just as we prepared to complete the tubes for Alfredo, a new issue emerged during evacuation—gas vapors began releasing from the internal plates. Despite using the same materials, supplier, and cleaning process, the results unexpectedly changed. Our lab is now fully focused on resolving this challenge, with special attention on improving the blackening process and achieving the highest level of plate cleanliness.

New Discoveries Through Practice

At first, we aimed to create the anode plate as a single-piece stamping—but that quickly proved unfeasible. Instead, we now laser-cut the side wings and form them using a bending machine before joining them with the base plate after blackening. Surprisingly, this method turned out to be the most straightforward and effective solution.

A More Robust Testing Stand

We’ve built a new testing stand specifically for the H nixie tubes. Why? Because these tubes demand significantly higher current—just a single illuminated digit consumes as much power as an entire Puri clock.

Why This Shape?

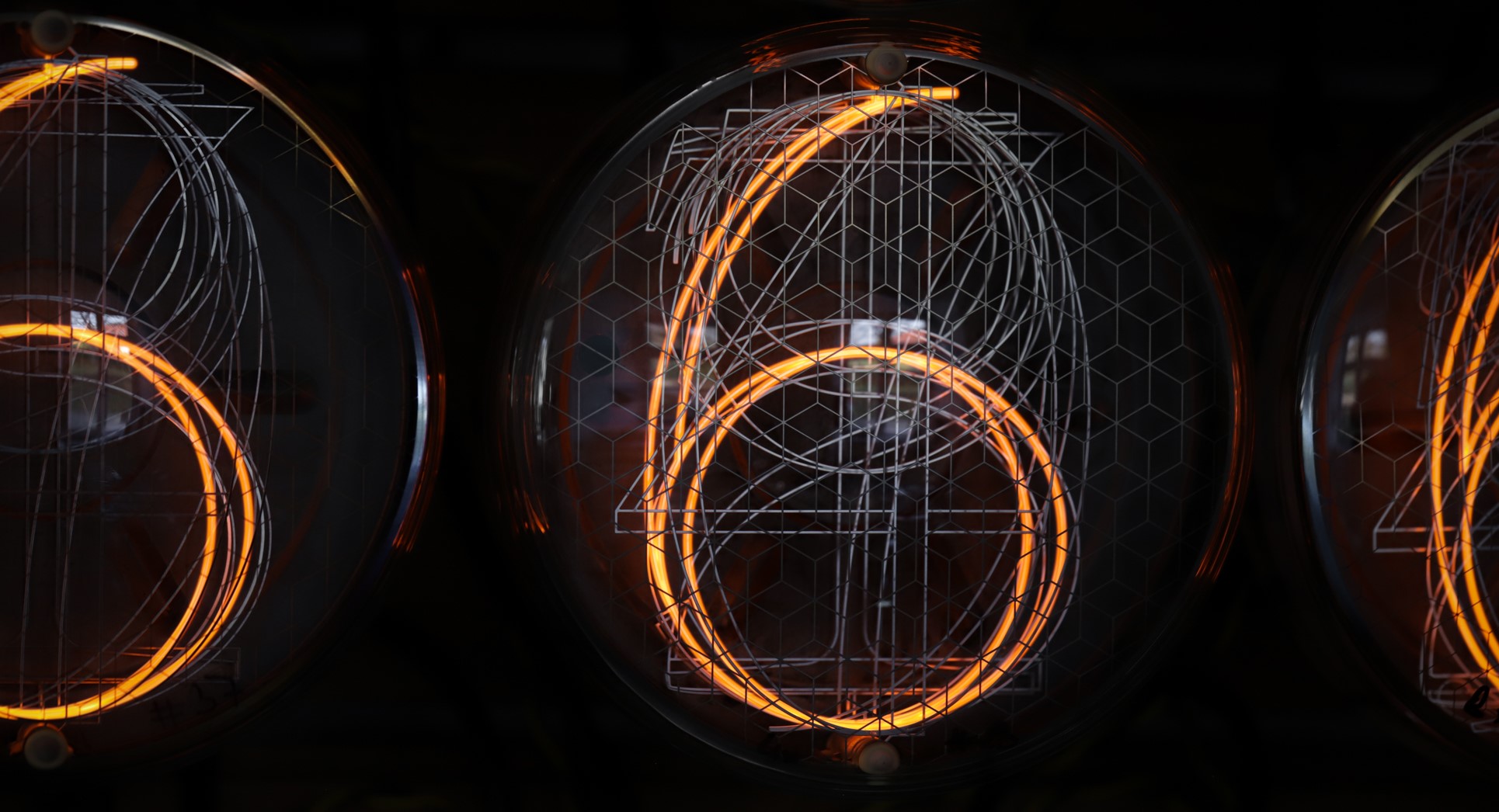

You might wonder why we chose this particular form. It’s driven more by function than aesthetics—the curved shape is inspired by CRT screens, whose geometry has been proven to withstand internal atmospheric pressure. This structural integrity is essential for a nixie tube of this size.

A Clean, Uninterrupted Appearance

We wanted to avoid a visible socket that would disrupt the visual harmony of the design or require a circuit board protruding from an otherwise clean panel. A front view focused solely on the digits and glass felt ideal—leaving the entire structure and electronics fully concealed from sight.

The Glow That Captivates

Just like with the R nixie tube, the most captivating feature is the glow itself. It fully draws you in—dazzling and immersive—pulling your attention into the gentle rhythm of changing digits until everything else fades away.