Confirmed by the old documents and witnesses.

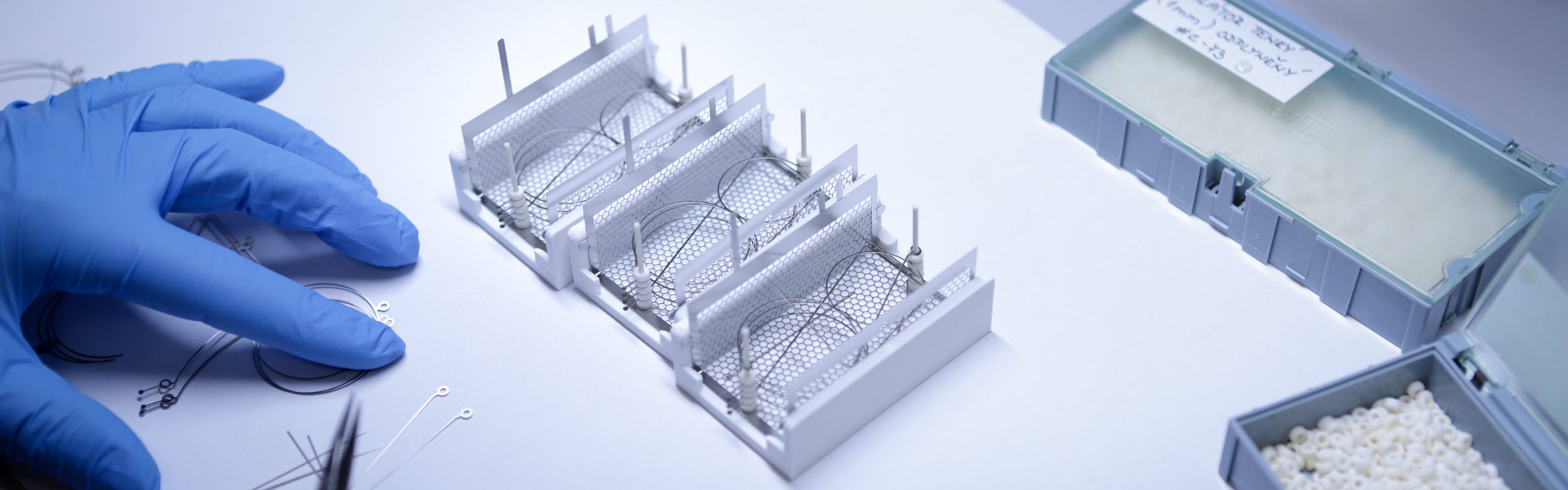

Dalibor: "In the beginning, when I started learning the nixie tube technology, there were hundreds of specific questions I didn't have answers for. What is the exact composition of the gas inside the nixie tube? What pressure has the gas inside the nixie tube? What level of vacuum should I reach to make the nixie tube clean enough before filling it with gas? Should I reduce the oxides on the digits in the hydrogen furnace before the assembly?

I intensively searched for documents describing manufacturing in the old times. I found that the documents were mostly focused on the production of radio tubes, completely ignoring nixie tubes. I also searched for the witnesses of the old nixie tube production lines. In my home country, the Czech Republic, we had several tube factories, all under the Tesla brand. The biggest one, Tesla Rožnov with over 3000 employees and own "vacuum high school", produced all vacuum tubes except nixie tubes. Nixie tubes were produced in a small Tesla factory in Vrchlabí. I could talk to a former director of the Tesla Rožnov factory, but he didn't know anyone from Tesla Vrchlabí. The decision to continue my own research was made..

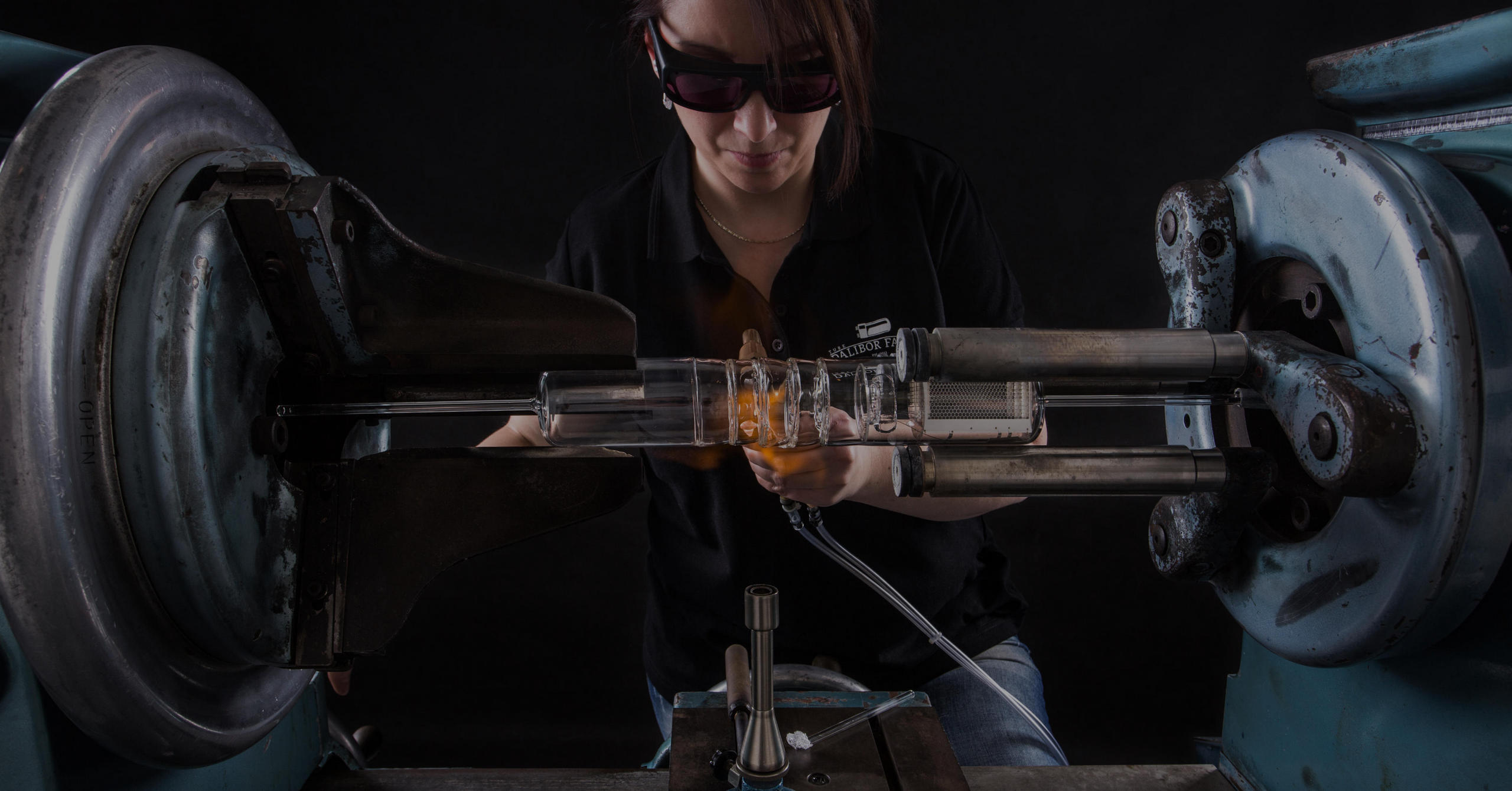

Ironically, to get the information I sought I had to develop the R nixie tube first. I made a video about making that nixie tube, and that video found its way to the old witnesses of the old production in Vrchlabí. I was also contacted by a person who had a complete set of original documents from a Russian factory describing the manufacturing of IN-1 and IN-2 nixie tubes. At that time, I already had the answers to most of my questions. Anyway, it was a great relief to find out that the answers we found are correct and we use the exact same procedures as the old engineers in the 1970s."