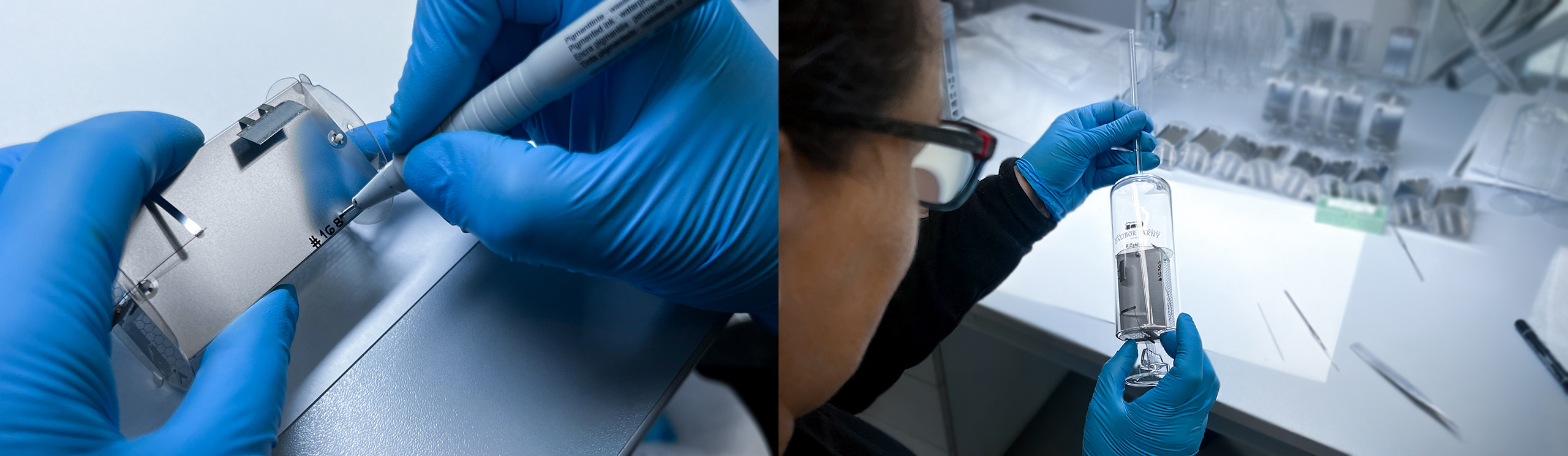

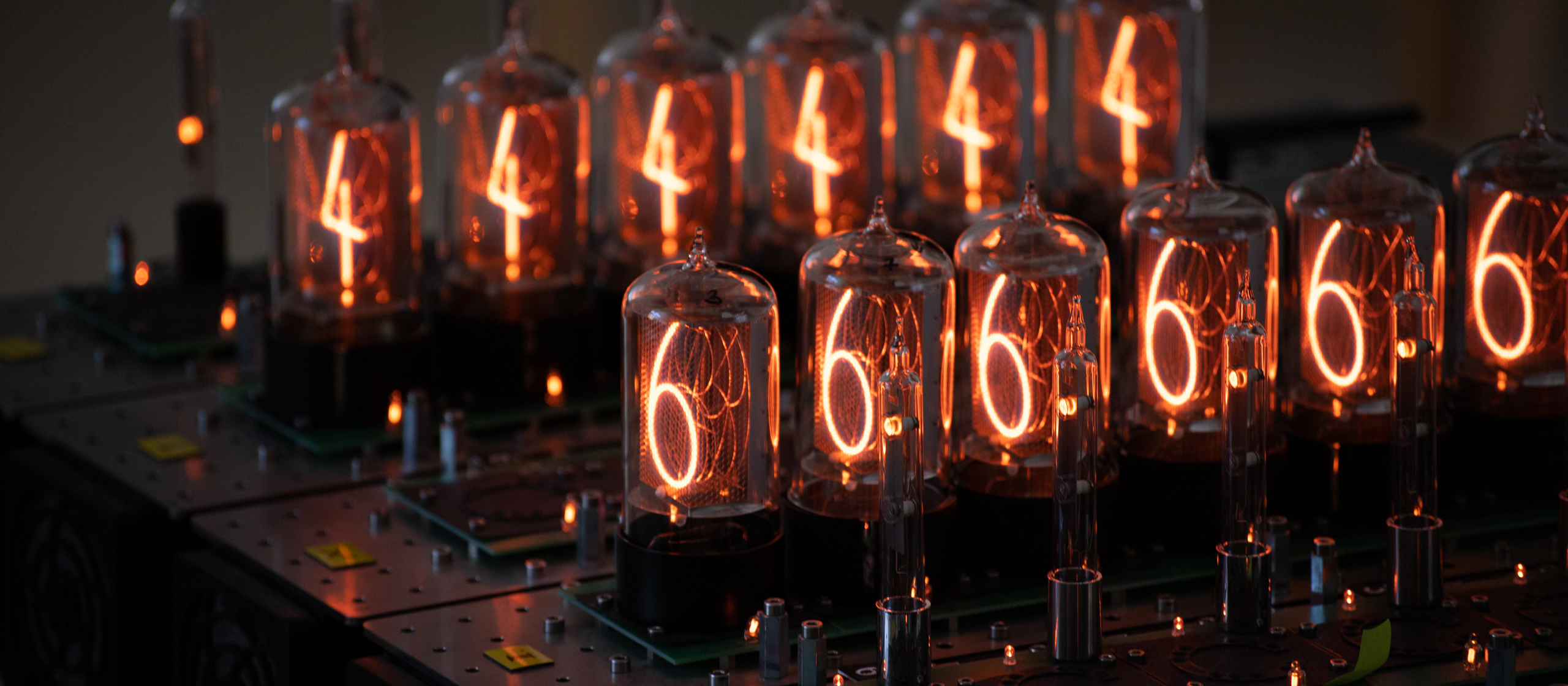

Handmade

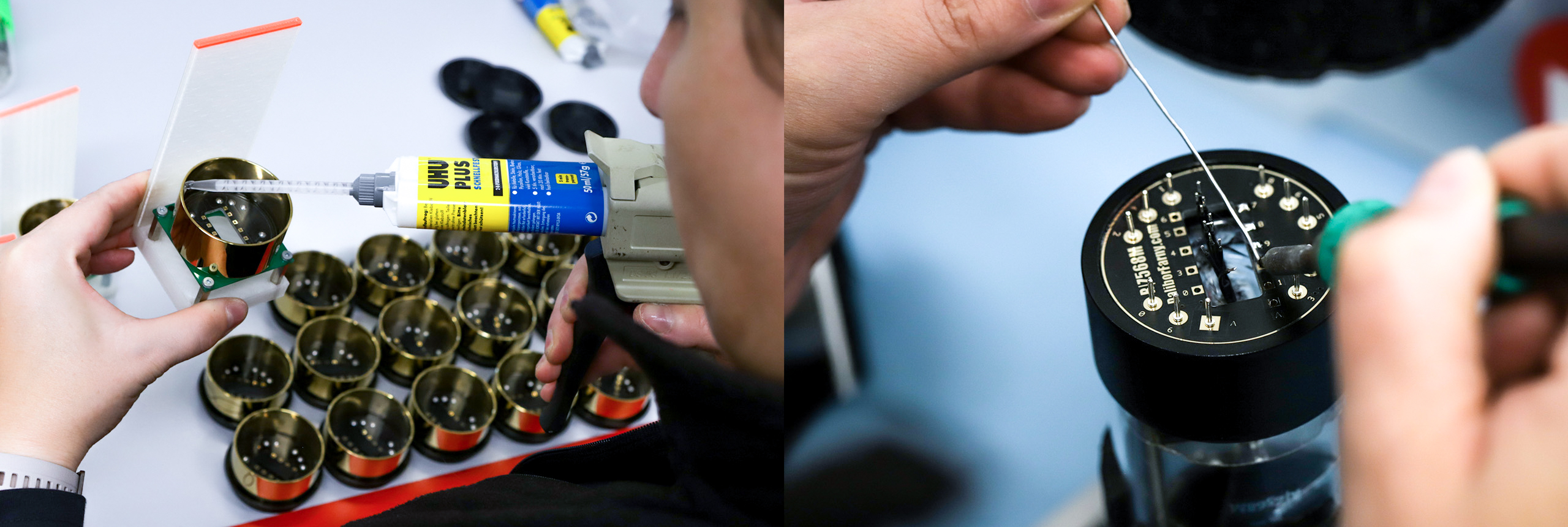

The vast majority of work on nixie tubes is done by hand, although we have already simplified many processes by construction of our own machines, some of which you can even find within your households.

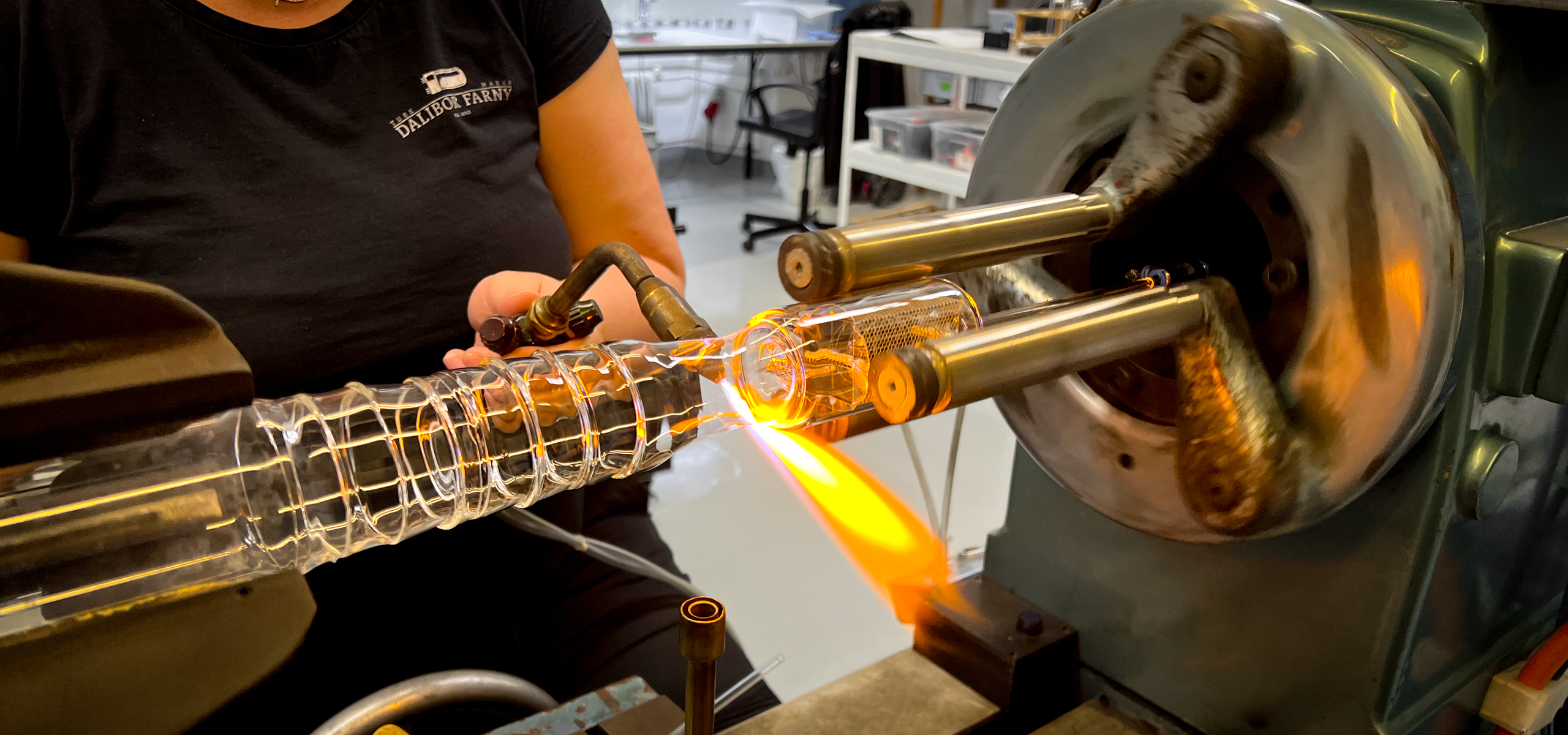

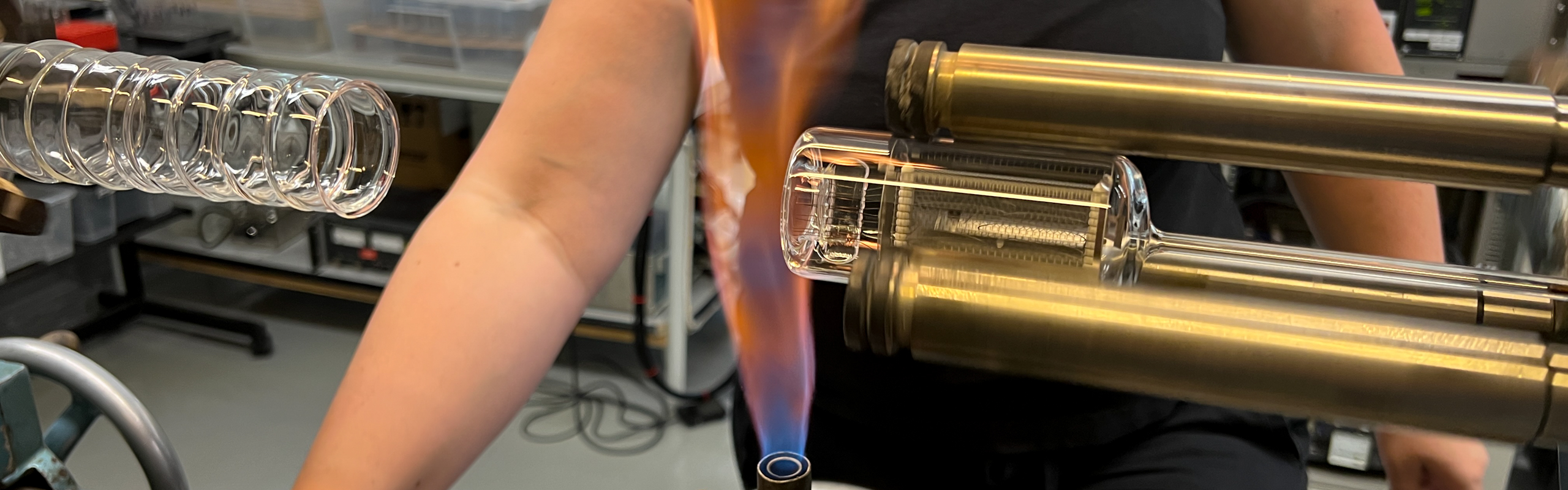

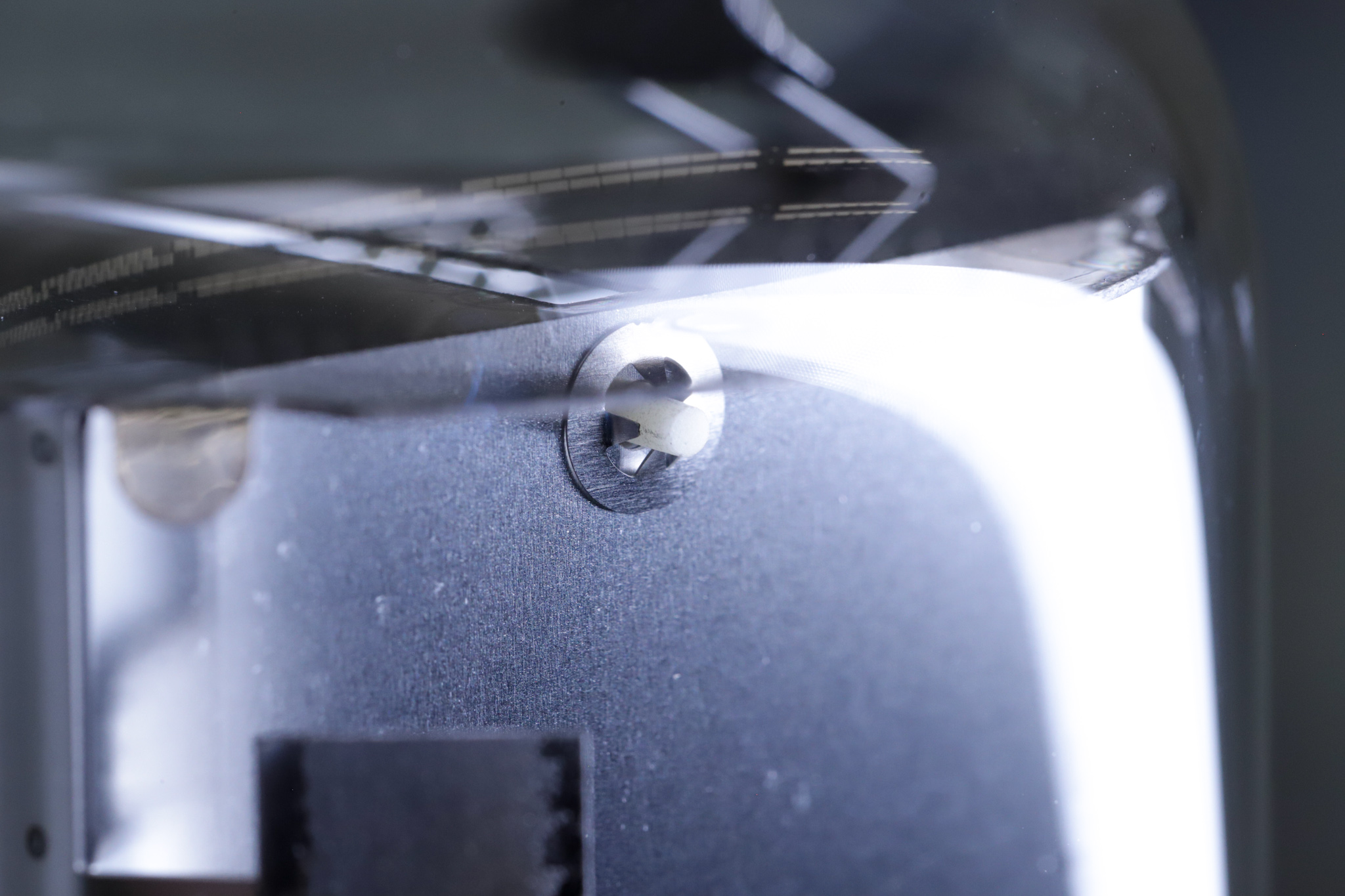

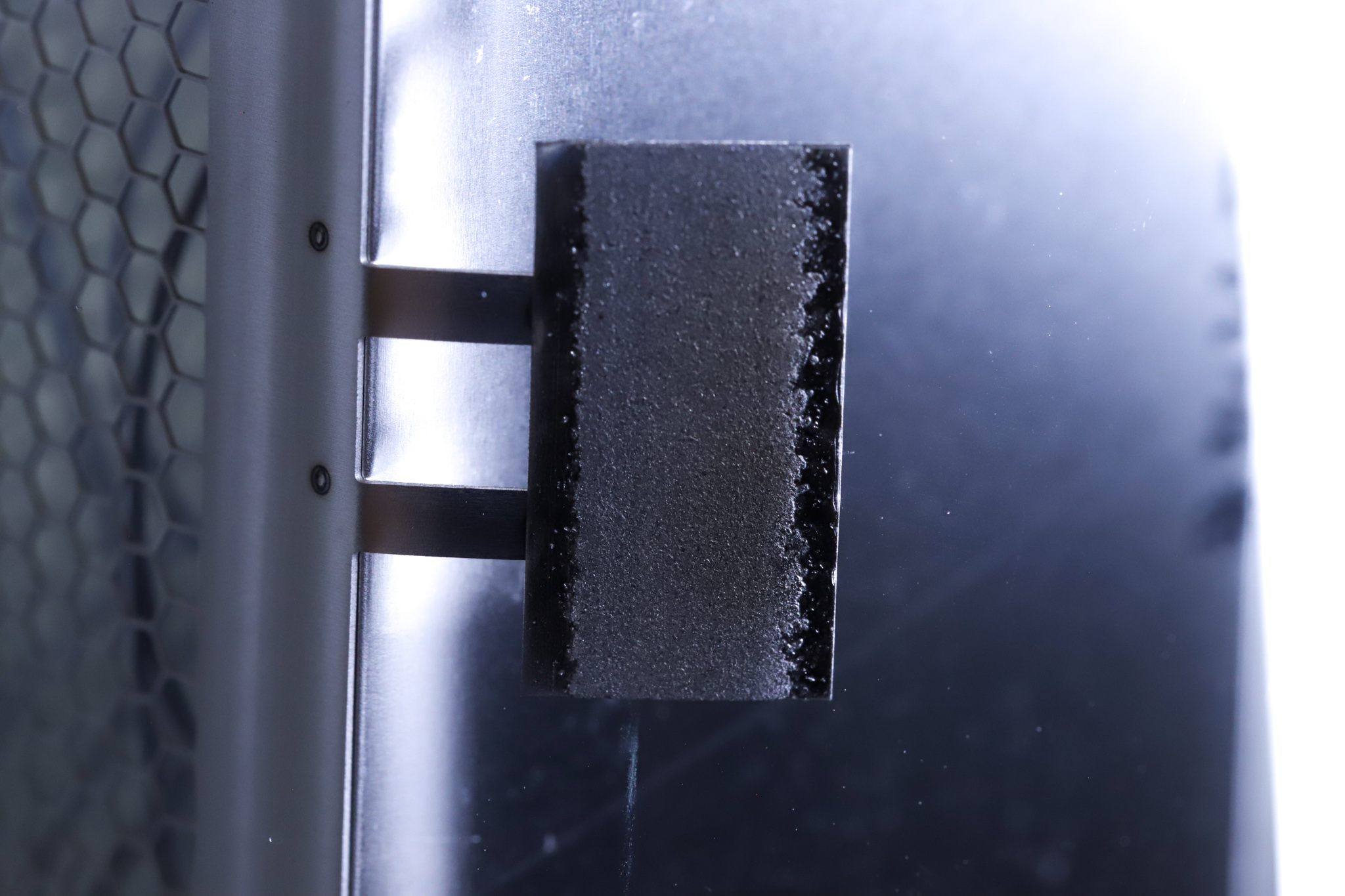

The hot work making us sweat is done on a glass lathe and during pumping of nixie tubes. The glass work has also required a lot of development and we are constantly improving every detail of our work.

But first things first.