Let’s look back at 2025, it was year full of difficulties but also of small victories.

Omnixie clock

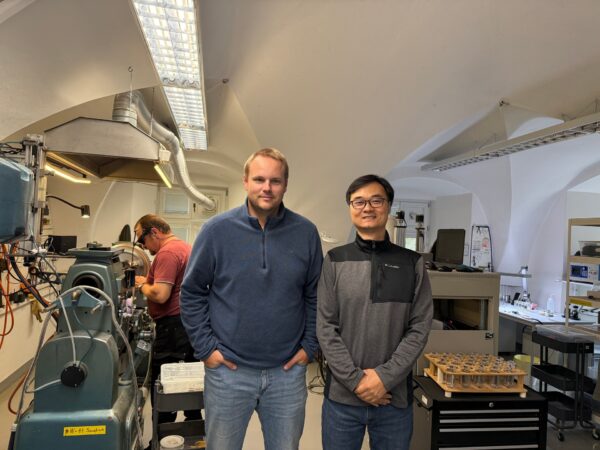

The most intensive project in 2025 was the Omnixie clock. This project was done in collaboration with Yan Zeyuan — skilled electronics engineer and designer, known for his beautiful Omnixie clock line.

Years ago, Yan built a large Omnixie clock using our R nixie tubes as a side project. It looked so good that we decided to turn the idea into a polished product.

Yan was responsible for the electronics and firmware, and for the mechanical construction of the base. My part was the nixie tubes, the final look of the clock (surface finishes), and the packaging.

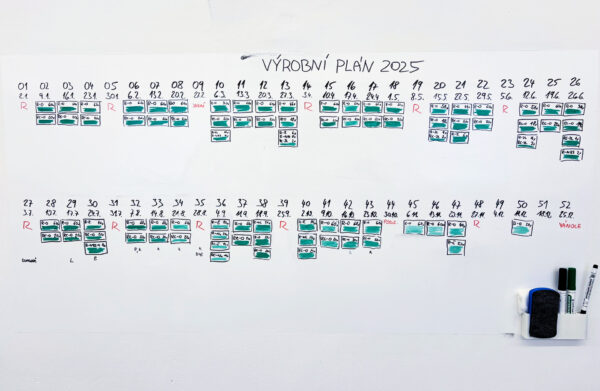

To keep the project realistic, we made a production plan for the tubes: 60 nixie tubes + 20 colon tubes per week. In 2025 we reserved 30 weeks for Omnixie production, and 9 weeks for spares and other projects — so you can see most of our tube capacity was reserved for Omnixie.

The biggest challenge turned out to be the Cerakote finish. We worked with a local applicator: we designed the process (cleaning, sandblasting, fixtures), and they applied the coating. Getting a flawless and consistent finish takes time and patience, so a lot of effort went into making sure we had enough perfectly coated parts ready to match the tube production.

Omnixie Graphite Gray is planned as a 300 pcs limited edition. We managed to make nixie tubes for all 300 clocks (big thanks to the team), but we completed 200 clocks in 2025. The remaining 100 clocks will be finished in 2026.

Urwerk Space Time Blade: Black

Urwerk’s SpaceTime Blade is a rare collaboration where we translated Urwerk’s design language into a functioning object built around a completely new kind of Nixie tube. At the beginning of 2025 we delivered the last pieces from the 33 pcs series.

This project gave us room for ideas that would be very hard to use in normal series production, simply because they are difficult. One example is the digit design: instead of simple “wire” shapes, the numbers use a fine mesh to create large glowing areas.

The clock consists of roughly 1,500 components, and many of them are custom-developed and custom-made. The manufacturing was challenging — but the administration and coordination around so many parts was sometimes just crushing.

In the end, Space Time Blade became one of the most daring and boundary-pushing (cliché, but true) nixie clocks we have made so far. It raised the bar for us — and it also gave us a lot of ideas for the future.

Boring improvements

2025 was not only about new products. A big part of the work was less visible: building a better platform for production — so we can make clocks more efficiently, keep quality high, and slowly move from “everything depends on me” to a process that can be handed over to the team.

It’s not the kind of work that looks exciting in photos, but it’s the kind that decides what we will be able to build in the next years.

The economic environment is not easy for anyone right now, and we feel the pressure too. We don’t want to lower standards, so the only way forward is to remove chaos, standardize what can be standardized, and improve how we work. It’s the boring kind of progress — but it’s what makes the dream sustainable.

One concrete step was taking back two rooms at the castle that we had given up in 2023 to save costs.

The first room will become a dedicated storage room. The goal is simple: the inventory numbers in the system should always match what is on the shelves. This was very hard when storage and packaging lived in one shared room.

The second room will be dedicated to clock assembly. We want a clean, focused space with separate work areas — for example one table for mechanical assembly, and another for soldering, testing, and firmware flashing. This will be separated from the R&D tables, which are (by nature) always messy and hard to keep tidy.

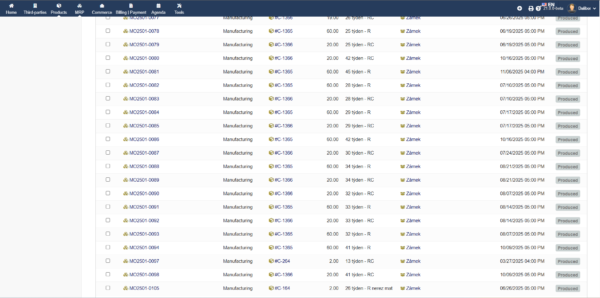

Another part of the “slow improvements” is building a repeatable process: an annual manufacturing plan, weekly manufacturing orders, purchasing order, and an inventory system that helps us plan and track what is actually happening in the workshop.

Over the years we tried several ERP systems, and each one had some issues for our type of work. In the end, we anchored at Dolibarr — a self-hosted, open-source ERP that fits our needs best.

It is far from perfect, but compared to the other options, it feels like we have to bend it the least to match how we really work. That’s what matters.

Team update: glassblowing

In 2024 we hired a new in-house glassblower, Patrik. In 2025 he became fully trained and can now work independently. This is a huge help for our productivity.

Glassblowing skills are rare today. The Czech Republic has a long glass tradition, but most technical glassblowers are located in the north-west of the country, while we are based in the south-east. In our region, you can sometimes find people with experience in artistic (lampworked) glass, but technical glassblowing is a different world.

Even when you find a talented glassblower, the company still needs to invest a lot into training. In our case, the key skills are making reliable glass-to-metal seals (the most critical part of the nixie tube) and sealing the glass envelopes.

On a personal level, this was also a big morale boost. After we had to shrink the team in 2023, progress like this reminds us that investing into people and skills still makes sense — and it pays back.

Retail partners

Most of our business is online. People discover our clocks online, they see photos online, and they order online. But one question keeps coming back: “Can I see it somewhere in person? And honestly — a nixie clock is one of those things that looks good in photos, but it looks even better in real life. In 2025 we started working with two new retailers, so you can experience the clocks in person.

Maison Davis — Zermatt, Switzerland

Zermatt is a famous mountain resort town at the foot of the Matterhorn — beautiful, but also usually quite busy and full of visitors. Maison Davis is a luxury concept store and gallery located in the heart of Zermatt. The story behind it is very human: it started in 1987 with Pieter Davis, originally from Rotterdam. After working on antiques and cars, he opened Maison Davis and gradually built it into a place focused on unique watches, jewelry, and design objects.

In 2017, his son Julian Davis joined and helped transform the store into today’s concept store / art gallery, mixing tradition with new ideas. In 2019, Julian’s close friend Robin Charpentier joined as well, so it really became a “family + friends” project.

Infinity Watches — Prague, Czech Republic

The second new partner is Infinity Watches in Prague. They focus on microbrands and independent watchmakers, and they built a place that feels more like a watch lounge than a typical store — you can take your time, talk watches, and explore.

Infinity Watches is run by Ondřej and Bhanu. Ondřej is a watch enthusiast and passionate photographer (his macro photography is used in publications and brand catalogs). Bhanu has a strong watch media background — he worked as editor-in-chief of Revolution USA and has written for major watch communities and magazines.

More retailers: aside from these new partners, you can find the full list on our Retailers page — including:

- Uhrsachen (Bern, Switzerland) — a long-running watch specialist in the old town (Kramgasse), known for a carefully curated selection.

- Jürg Brunner (Olten, Switzerland) — a watch and jewelry studio that also carries our nixie clocks, alongside other design-focused time objects.

Solar power

A few years ago, when electricity prices in Europe went up very quickly, we started building a 20 kW solar power system to reduce long-term energy costs.

Because we work in a 16th century castle (cultural heritage), we obviously can’t — and don’t want to — put solar panels directly on the castle roofs. Instead, we used the roofs on Dalibor’s house and the garden shed (some of you may remember the early days when we were based there).

The goal is to feed electricity into the grid and offset the electricity bill at the castle. This is not as efficient as consuming the power where it is produced (we still pay distribution costs), but it’s the only realistic option for us.

The investment should pay back in roughly 5–7 years.

To be clear, electricity was never our biggest cost. In 2023, electricity was about 1.5% of our annual costs, so it wasn’t a top priority. But it still makes sense to stabilize expenses where we can. In 2025, electricity costs made about 0.75%, and we produced roughly 30% of our yearly consumption from solar. Not bad.

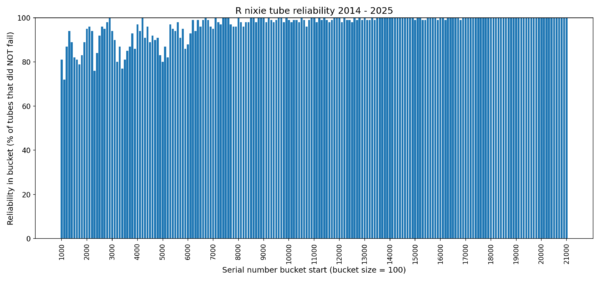

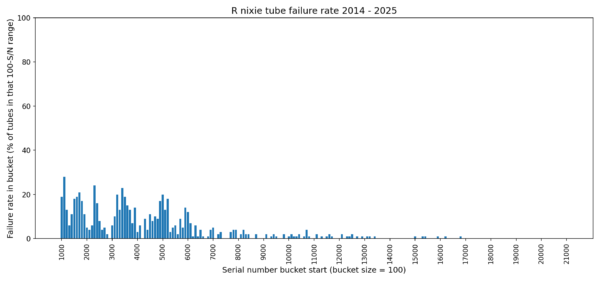

Reliability rate by serial number

Reliability rate by serial number