Estimate reading time: 3 minutes

The most difficult part of the tube will be definitely stems. More than 10 pins must go through, all vacuum tight of course, on small area. I have some ideas about how to do it properly, but the set up will be pretty complex. Furnace with inert atmosphere, high temperature (around 1000ºC), some kind of pressure (maybe just some ballast weight on the top of the mold..).

Test – a piece of carbide silicate (SiC – common carborundum) at a layer of vermiculite, great thermal insulator – low thermal capacity and high melting temperature (above 1300ºC). All on a terracota pot.

After a few minutes in microwave oven.. The real color is yellow, I guess 1000°C (I hadn’t a IR thermometer what I have now – gonna measure it)

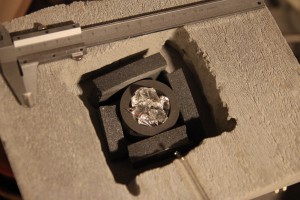

A carbon mold filled with lead glass and some dumet wires, carbide susceptors around the mold. The gray material around is common block from cement used in buildings (Ytong etc..). Notice the thin glass tube with rounded end on the bottom – it should act as a optical fiber to let me know about the temperature inside..

Some vermiculite around for better insulation..

overall overview (notice my new glass blowing torch on the right – blue something 😉

This try was unsuccessful. There was a lot of moisture in the block, so it went only on 80ºC, the moisture behaved like a susceptor for the microwaves, almost no energy went to mold itself. I let the oven run for 45 minutes hoping it evaporates all the moisture and then increases the temperature around the mold, but it was still the same after that time.. I think even after evaporating the moisture from it, it would absorb it back from the air around when left out of the oven..

Another try, just with a handtorch, just to see what the glass does on certain temperature.. I gave it 10 minutes of heating, on the top measured 750-800ºC by IR thermometer. The glass melted, but wasn’t able to flow enough.. I will try the real lab furnace.