About the author : Dalibor

Getter cutter machine

I am building a machine which will cut getter strips to individual pieces with minimal attention from the operator. The process must be clean, precise and reliable. It is not very difficult project, so I decided to take it as first project for my planned youtube video build series. I am learning work with camera and eliminating mistakes I do in taking the footage (e.g. loose microphone cable = no sound, autofocus on = shaky footage, forget turn on lights = noisy image etc..).

Getter cutter feeder

Getter cutter feederIn first video, I redesigned a feeder part. Now it needs lower amount of air thanks to shorter paths of the cylinders (= less load on compressor, less noise), the frame is more rigid, I can change the length of the getter in a seconds..

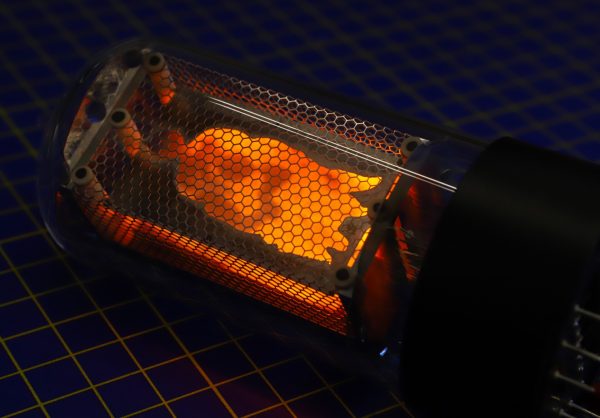

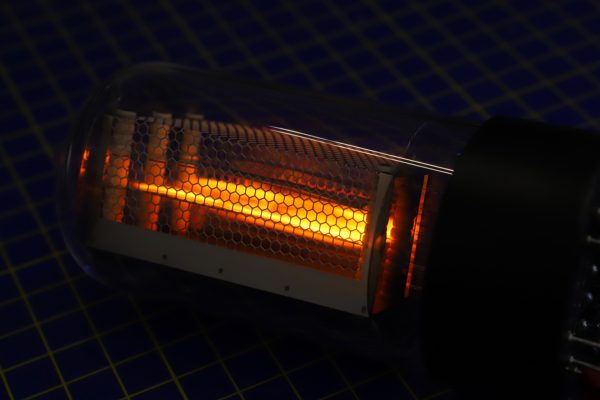

Nixie tube I didn’t make

During first week of January, I noticed weird behaviour of my colleagues.. Renata was helping Sebastian with 3D printer (why?). Sebastian was hiding a 3D print from me (why?). Lenka was nervous when I saw her cleaning parts for next batch of nixie tubes (why?). Few days later it all cleared up, I celebrated my birthday and they gave me special nixie tube. Silhouette from a photo of my children, etched from steel sheet, made as a nixie tube in a 3D printed case :-) This was first nixie tube which was made by us completely without me, they’ve learned something! It was real surprise and confirmation that we are successful in distributing the skills between us. Nobody is irreplacible now :-)

Motion sensor for our clocks

We started working on a motion sensor which will be able to control customer’s clock and turn it off when there is nobody around. The nixie tubes will be powered only when the motion sensor detects a movement (somebody in a room can see the clock). When there is no movement (nobody present), the tubes will be turned off.

This will prolong tube lifespan as well as save electricity (1W per tube). Currently the clocks can be programmed to turn on/off tubes periodically by night mode feature – each hour in a week can be addressed individually. This feature handle many situations, but when customer’s schedule is variable, motion sensor is the way to go.

Our motion sensor will be a small separate wireless box in anodized aluminum body. This will allow customer to place the module to a sweetspot where it can reliably detect motion in the room. This is sometimes problem with sensor built in the clock – the sensor detects motion right in front of the clock, but this might not be the most frequented place in the room.

The sensor will connect to wifi router wirelessly (just like the clock) and will be powered from a battery. It will recharge from a USB. We are now running first tests to find out how often we can wake it up to check the movement, how frequently initiate connection with wifi etc. to get best balance between battery life and functionality. Our goal is to get to 6 months of regular use (motion detected many times per day).

I asked Radim (our junior electrical engineer) to develop this sensor including software. I wanted him to have maximum freedom with minimum input from me. I tend to control the things on too low level, so in this case I wanted just control the criteria (functionality what we want from the module) and the outcome. I was pleasantly surprised when I saw Radim changing my suggested components with more suitable ones (e.g. lower power), making his own test circuit boards and generally improving and solving the circuitry. Sebastian was also help in this project, I guess it is difficult not to check out what a coleague is working on :-)

Motion sensor prototype

Motion sensor prototype

Thank you for attention, see you at the next blog post :-) Consider subscribing for our newsletter: https://www.daliborfarny.com/newsletter