R is the first nixie tube to be produced since the 1980s.

Let’s rewind to 2011. By then, nixie tube manufacturing was a thing of the past.

Not a single factory had survived the rise of modern digital displays. For over 30 years, nixie tube technology had been forgotten—abandoned and left to fade from memory.

Names like Burroughs Corporation, National Electronics, and Raytheon in the U.S.; Mullard in the U.K.; Gazotron in Ukraine; Philips in the Netherlands; RFT, Telefunken, and Siemens in Germany; Rodan in Japan; and Tesla in Czechoslovakia—all once active in nixie production—had long since shut down their lines. The delicate machines and tools, once operated by skilled engineers and technicians, were dismantled or scrapped.

With time, the intricate knowledge behind nixie tube production faded—lost along with the tools, and with the people who once knew how to use them.

Where Nixie Tubes Were Born—and Forgotten

The factories shut down, and with them, the tools and knowledge that once gave nixie tubes their glow.

A Reckless Beginning

It’s 2011. Dalibor—a young fool from the Czech Republic—stumbles upon the quiet beauty of nixie tubes. Intrigued by their simple glass envelope and the fine metal structures inside, he assumes making one will be a pleasant little hobby.

With no experience in manufacturing, he jumps in headfirst—naively underestimating the brutal realities of physics, chemistry, vacuum systems, and all the complexities of tube production. Yet despite countless setbacks, in 2013, the first prototype—R|Z568M—was born.

Nixie tubes resurrected.

Built through trial, error, and stubborn curiosity—the first working prototype, R|Z568M.

After decades of silence, the R tube marked the return of nixie tube production.

Honoring the Past

The R|Z568M is inspired by the original German Z568M nixie tube. We kept the name as a tribute to the engineers who designed it in the 1970s, with “R” standing for resurrection. Later, we simply called it “R”—a cleaner name for the tube we consider the most elegant of all.

The Path to Perfection

They say mastery takes 10,000 hours—we say it takes 10,000 tubes. That’s how long it took us to get the R just right.

In the 1970s, the nixie tube’s role was purely functional—just to display numbers. In the 21st century, it must also be beautiful.

Confirmed by Old Documents and Witnesses

Dalibor:

When I first began exploring nixie tube technology, I faced hundreds of unanswered questions. What was the exact gas mixture inside a tube? What pressure should it be? How deep must the vacuum be to ensure a clean fill? Should the oxide layer on the digits be reduced in a hydrogen furnace before assembly?

I searched obsessively for documentation from the original manufacturers—but most resources focused on radio tubes, not nixie tubes. I also tried to find people who had worked on the original production lines. In the Czech Republic, several factories operated under the Tesla brand. Tesla Rožnov, the largest—with over 3,000 employees and its own “vacuum high school”—produced many kinds of tubes, but not nixie tubes. Those were made in a small Tesla facility in Vrchlabí. I spoke with the former director of Tesla Rožnov, but he knew no one from Vrchlabí. At that point, I made the decision to continue my research independently.

Ironically, it was only after I developed the R nixie tube and published a video about it that everything began to connect. The video reached former workers from the Vrchlabí plant. Around the same time, I was contacted by someone who possessed a complete set of original documents from a Russian factory that described the production of IN-1 and IN-2 nixie tubes. By then, I had already discovered most of the answers myself—but seeing them confirmed in these original materials was deeply validating. In the end, we learned that many of the procedures we use today match those of the engineers who came before us in the 1970s.

Achieving Reliability

The R tube taught us the true meaning of reliability. There’s a brutal difference between a functioning lab prototype and a product that endures years of real-world use.

Where It All Came Together

With the R nixie tube, we were finally able to create our first complete clock—the Zen Nixie Clock.

Technology

The R tube became our teacher. It led us to understand the full scope of nixie tube technology and pushed us to design or acquire machines and tools for every step of the process. It laid the foundation for all future projects to come.

The Team.

The R nixie tube, together with the Zen Clock, made it possible for us to hire our first employees and begin building the team that now serves our customers.

Handmade

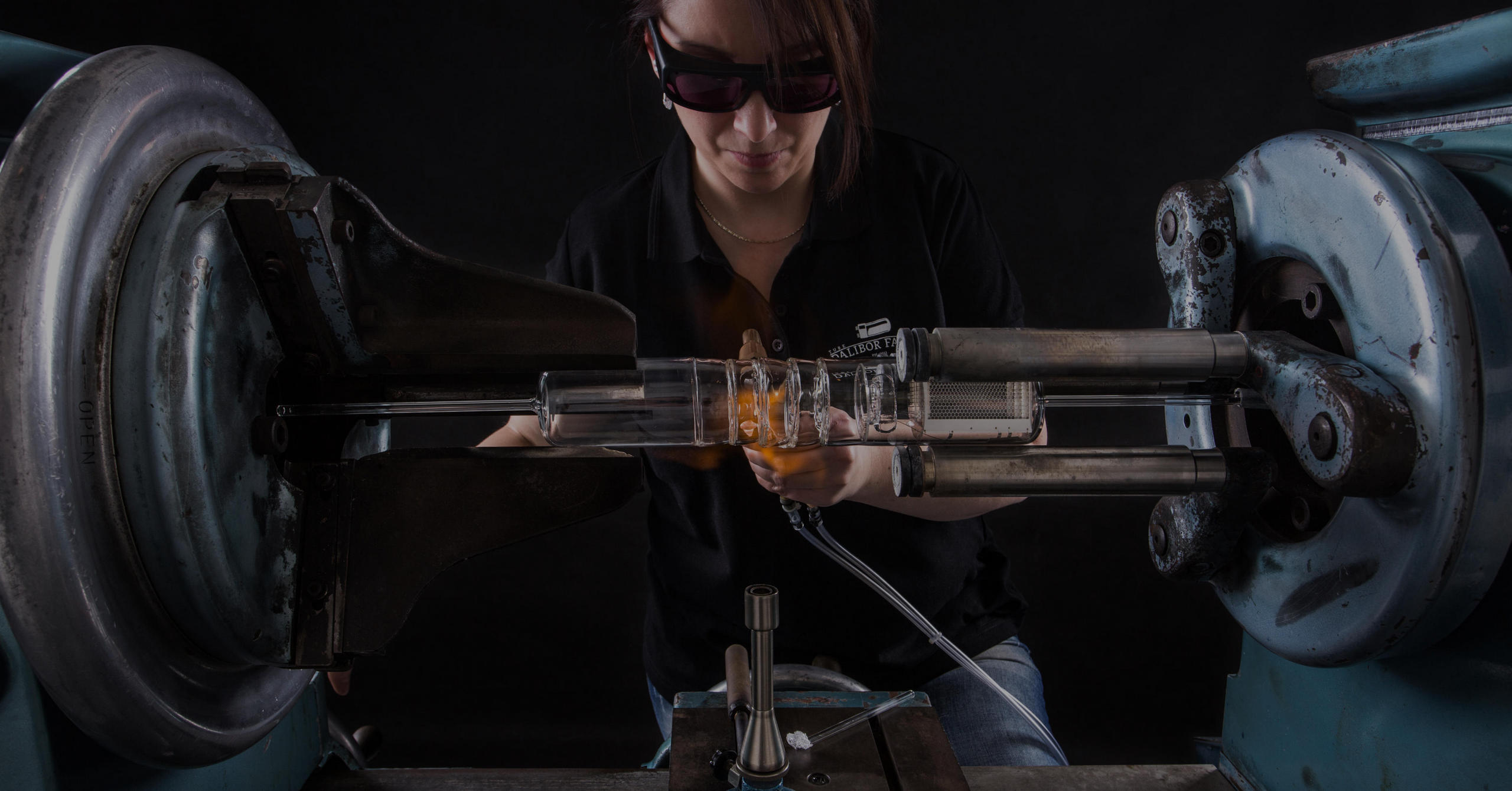

We aim to make each nixie tube match the others—uniform in shape, perfectly aligned in the clock. The more we practice, the closer they become. Yet in the end, it’s the small variations that give them character—making each piece more human, and often more cherished by our customers.

Lab in a Castle

Thanks to the R nixie tube, we were able to rent space in a local castle—cold and humid, but with a unique atmosphere and character. Surprisingly, it offered the same quality of space as commercial buildings, but with far more personality.

Quality control.

The R tube made one thing clear: without rigorous quality control, even the best design won’t endure.

Cleanliness

Much like quality control, cleanliness became one of our obsessions—approached with almost paranoid seriousness. In nixie tube production, even the smallest contamination can ruin everything.

Nixie Tubes Always in Reserve

We always keep a stock of R nixie tubes so we can quickly solve a nixie tube failure or sell a replacement.