About the author : Dalibor

I used to spot weld wires for electrodes by placing them across and weld. That works but doesn’t look well and I think it makes strain in the glass when sealed (more steel wire in glass, different thermal expansions). I decided to make a simple jig from some aluminum junk so that I will be able to produce nice lead-in-wires for my experiments.

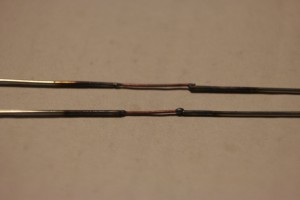

There is a photo of industrial made lead-in-wires, the red part of the wires is dumet wire. Notice the blueish part of the bottom wires – it is sign of that wire was heated (during welding).

My jigs, the black sticks on the top are brass electrodes from spot welder, they are inside the hole in aluminum, tighten by screw.

There are wires mounted in the jigs, steel wire on the left, dumet on the right. The result depends on the length of wires going from the jig. Big scissors are used for cutting the wires to make the cut surface flat.

These are my first welds, it will need a lot of practice, but I am sure I will be able to make satisfactory lead-in-wires.. Although these welds doesn’t look well, they are strong..